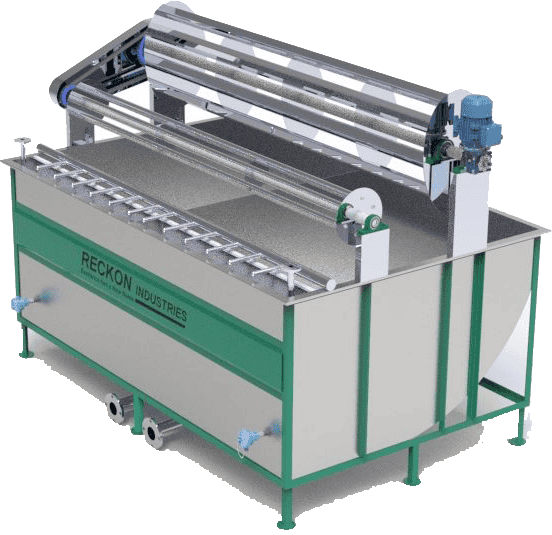

Features & Specification:

- Completely Made Up With Pure Stainless Steel 304 Grade Sheet

- Reduction Gear For Longer Life Span of Machine

- 1 Hp Motor 3 phase or Single Phase

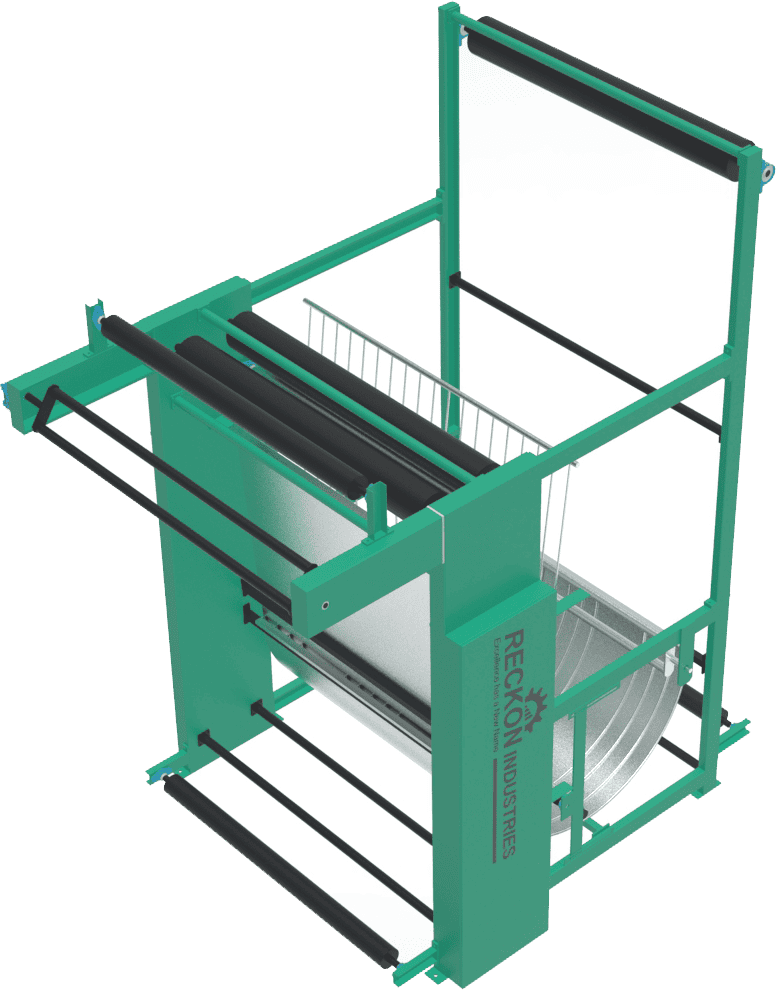

WINCH Detail

Winch Machine (Rope Form) is innovatively designed to be used in both process sequence and fabric that could be treated. The main emphasis of this machine is to wash those fabrics that are not able to be treated with a conventional washing machine, thus saves water and energy. Furthermore, this machine also reduces lengthways tension occurred in fabric, avoiding shrinking. The best thing about Winch Machine is that it is ideally suitable for woven fabrics that are made up of cotton, cotton/polyamide, cotton/polyester, cotton/viscose and cotton/viscose/polyester.

The rope processing equipment that the market has had to offer so far, has rather limited the application of this technology. This applies to both the process sequences and the fabric that could be treated.

Rope processing is a technique that was used even before the arrival on the scene of modern continuous washing ranges. A few years ago the main concern was to conserve water and energy, with this new machine the main emphasis is on a wider range of application. In particular, the aim was to cater to those fabrics that could not be treated on conventional rope processing machines, owing to their tendency to crease, e.g. closely woven fabrics.

Another major consideration was the further reduction of lengthways tension in the fabric. Nowadays, in knitted fabric finishing this is a very important point, with a view to reducing residual shrinkage.

In principle of rope washing, all those fabrics that can be processed in rope form on conventional machines. e.g. circular knit fabrics made of cotton, cotton/polyamide, cotton/polyester, cotton/viscose, and cotton/viscose/polyester.

The new thing in this machine is that, it is also suitable for woven fabrics made of cotton, cotton/viscose. cotton/polyester or linen and blends which had been a problem.