Disperse printing has been integral part of the textile polyester printing .Since the introduction of polyester fabric as a low cost replacement of expensive silk fabric, there has been a tremendous boom for this fabric.

Polyester fabric has always been a very easy and cheap option to natural fibre and to print or dye this fabric is also not expensive job.

EVOMAX Detail

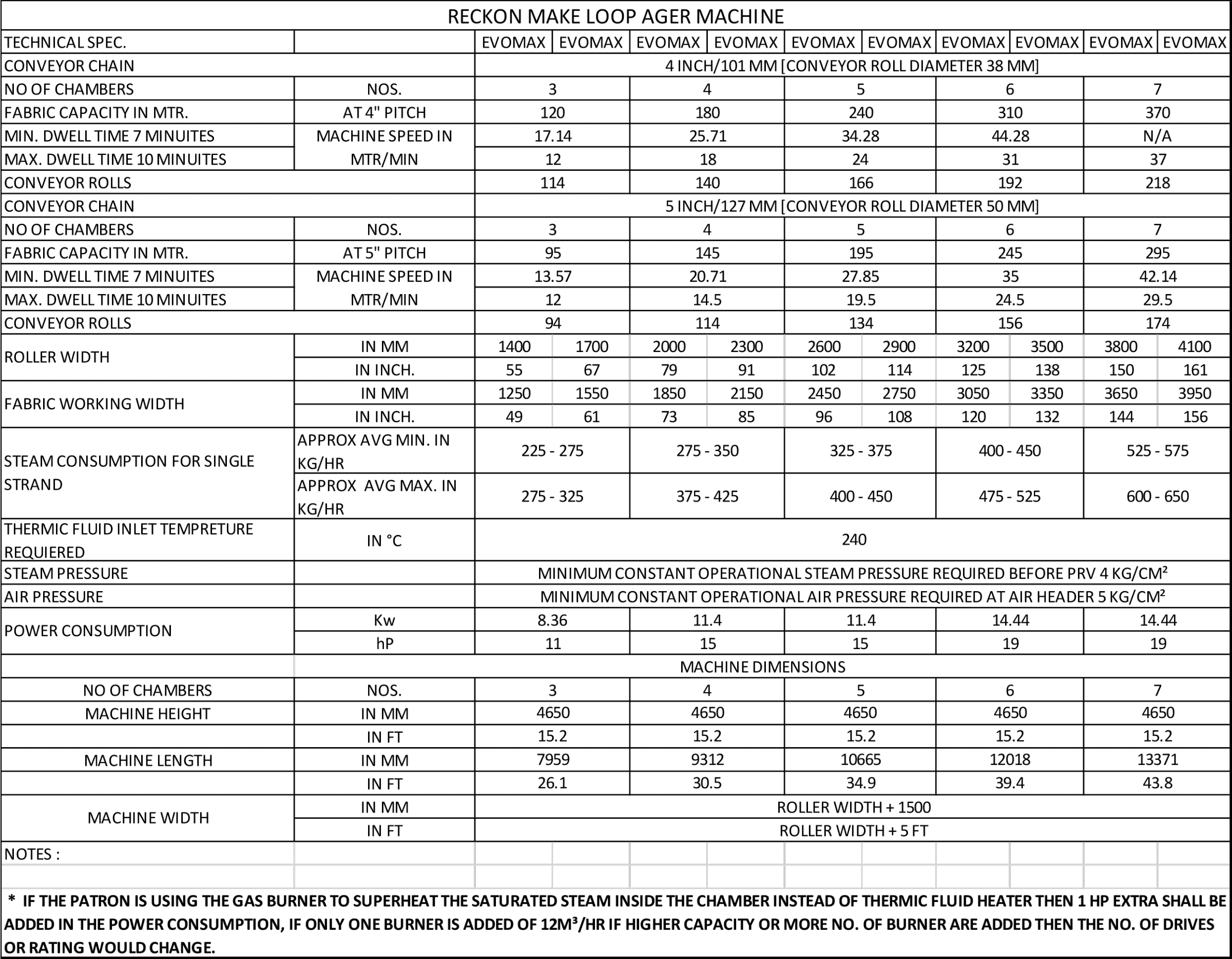

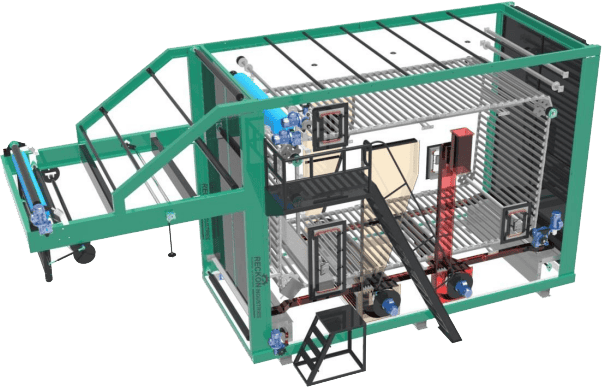

To treat the disperse dye of polyester fabric and its blends, RECKON INDUSTRIES offers you EVOMAX, which helps the patrons to achieve unmatched colour depth and brilliancy by super heating the saturated steam inside the chamber through thermic fluid heaters/radiators or gas burners. The consistency of heating and maintaining the temperature inside the chamber is managed by constantly removing the contaminated steam which is created due to area decapitation through exhaust system and introducing fresh steam directly on thermic fluid heaters/gas burner further recirculating it with the help of blowers, depending upon the production of the patron as well as the width of the fabric.

'RECKON INDUSTRIES' offers ‘EVOMAX’ model in a full stainless steel 316 as there is going to be steam interaction with fabric and EVOMAX can also be utilized for pigment prints by switching off steam line.

EVOMAX is available in LITE as well as PRO model depending upon the patrons.